Enginuity Power Solutions were engaged by a client who has a portfolio of property across Tasmania to assist in the development of a capital works package aimed at reducing energy consumption and lowering operation costs. A comprehensive audit was carried out of the equipment utilised throughout the site with particular attention paid to the heating, ventilation and air conditioning (HVAC) system.

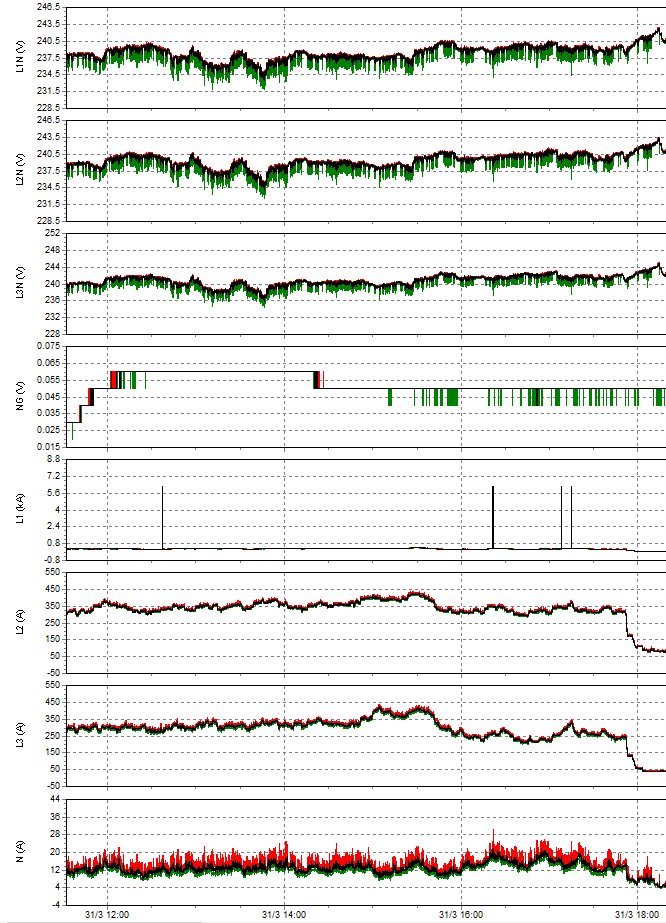

A power quality analysis of the building was carried out utilising the Fluke 435 Power Analyser. The purpose of the power analysis was to provide baseline data of the electrical system and to highlight periods of the day where power usage increases. This data was then utilised to assist in the identification of potential cost saving initiatives which could be implemented to increase the efficiency of the building; hence reducing operational costs.

Upon analysis of the data, it was evident there was an intermittent, very high spike in current occurring on a single phase of the electrical system. The spike appears to only last within the electrical system for a period of half a second or less. These types of faults have the potential to be very dangerous due to potential earth faults, but they can also result in substantial penalties regarding peak demand charges on electricity bills. When these irregularities were inspected further it was discovered that they were being caused due to a short in an electric motor.

When the data captured by the Fluke 435 Power Analyser was evaluated in conjunction with the monthly energy bill it was evident that these spikes in current were resulting in demand charges being inflated and the subsequent energy bill inflated.

Through the identification and rectification of this intermittent fault, not only was the safety of the installation maintained, but the annual energy bill for the site has also been reduced by approximately $10,000.